Overlanding Rig - Panda

Air System

When you're hitting trails, you want to be able to quickly air your tires up and down. Carrying a conventional portable pump wasn't cutting it - it took almost 40 minutes just to air up my tires after a day offroading! I had seen similar air systems set up in other vehicles to make the process more efficient, so I decided to build my own. The air system required substantial planning. Below you can see a BOM for all the required components.

-

ARB CKMTA12 Twin Compressor

-

1/4" NPT, 8mm OD Push-to-Connect Elbows

-

1/4" PT , 8mm OD Push-to-Connect Joint

-

8mm to 8mm Push in Coupler

-

8mm to 8mm 3-way Push in Coupler

-

1/4" NPT Brass Plugs

-

8mm OD, 5mm ID Pneumatic Hose

-

Aluminum Air Manifold

-

NC Series Brass Safety Release Valve

-

Haltec H-5265 Standard Bore Lock-On Quick Connect

-

ARB Inflation Kit

-

Air Hose with Quick Connect Fittings

-

Quick Connect BSP Fitting

-

-

VIAIR 92804 18” Stainless Steel Hose

-

18-8 Stainless Steel Flat Washers

-

Brass Pipe 3-Way Fitting

-

Brass Pipe Elbow

-

Prass Pipe Nipple

-

Milton S-684-4 1/4” MNPT Male Shrader Valves

-

Milton 1193 1/4” NPT Pressure Gauge

-

Kingston KMBVM Series Brass Mini Ball Valve

-

Pneumatic Hand Slide Valve

-

Shrader Valve Caps

-

Heat Shrink

-

1/4" Braided Nylon Sleeve

-

Teflon Tape

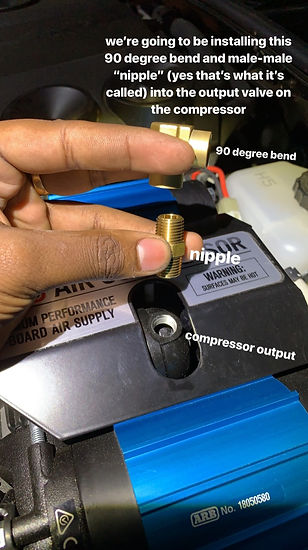

Mounting the compressor in the engine bay was a fairly simple task utilizing the RagoFabrication compressor mount. Next step was to plumb the output. I wanted to utilize the quick-connect fitting that ARB provided in their inflation kit, but I also wanted to split the output out to all four wheel wells through the air manifold. I started off with an elbow configuration that brought the output steel braided hose far too close to the plastic trim around the engine bay. That quickly changed to a tee configuration that routed the steel hose back and around the side of the pump, where it wouldn't affect anything else.

Here, I began assembling the manifold. A shutoff valve was mounted at the manifold inlet to ensure that the system can be closed when the quick-connect + hose are used. The pressure gauge, safety release valve, and hand slide valve are mounted to the manifold. Finally, the manifold outlet feeds the lines to each of the wheel wells.

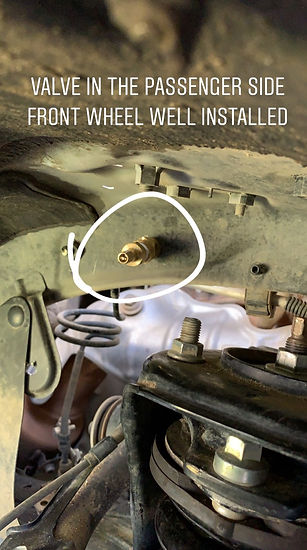

At each of the wheel wells, I assembled shrader valves with push-connect hose fittings. These will act as access points to the air system for each individual wheel.

Pneumatic hose was routed from the manifold to each of the wheel well shrader valves.

In order to create the four hoses that connect wheel well to tire, I began with a 48" length of pneumatic hose and some Haltec Lock-On connectors. Each end of the hose was connected to a lock-on connector via 1/4" NPT push-to-connect fitting. Finally, some braided nylon hose and heat shrink completed the set. Four hoses are now ready to be used with the air system.

Everything works! The hoses allow quick connection between wheel well and tire. The pump can quickly pressurize/depressurize all four tires simultaneously, which is incredibly convenient for adventuring.